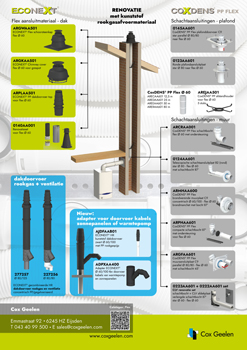

CoxDENS PP Flex

The CoxDENS® PP Flex flue system made of Polypropylene is, like the rigid flue systems made of PP, also designed for use with oil and gas-fired condensing heating boilers with a flue gas temperature up to 120 °C (Temperature Class T120).

CoxDENS® PP Flex can be easily shortened and, with the help of the matching connectors, can also be quickly, securely and firmly attached to the chimney cover on the roof and the wall or ceiling plates in the house. Particularly suitable for renovation, its great flexibility facilitates installation in the curves (bends) of existing chimney flues.

Especially developed for connection to condensing boilers

with a maximum flue gas temperature of 120°C (T120).

Specifications

- Polypropylene.

- Resistant up to a flue temperature of 120 °C.

- UV resistant.

- Operates in negative and positive pressure modes.

- Designed as a vertical flue system installation but is safe to run at angles up to 45° from vertical.

- Ø 60, Ø 80 and Ø 100/110 mm available in the colour white.

- System approval 5000 Pa (level H1).

- CE marked according to European standard EN 14471.

Product range

- Pipes in lengths 12,5, 15, 25, 50 and 80 meter.

- Couplings flex-flex and rigid-flex.

- Inspection pieces.

- Chimney bends 87°.

- Fire resistant wall plates with chimney bend and fire collar

- Ceiling plates.

- Chimney covers.

Safety

A flexible flue gas system is designed as a vertical flue system installation but is safe to run at angles up to 45° from vertical. In addition, we recommend that the inside of the shaft should be up to 2x the diameter of the pipe to prevent siphon formation. It is also necessary to place a 2 meter bracing bracket (spacer) to prevent premature abrasion wear. If the outside temperature drops below 5 °C, the flexible pipe must be warmed up before installing.

CoxDENS® PP is resistant to agressive condensates.

Media

► Installation instructions - filmed on location.